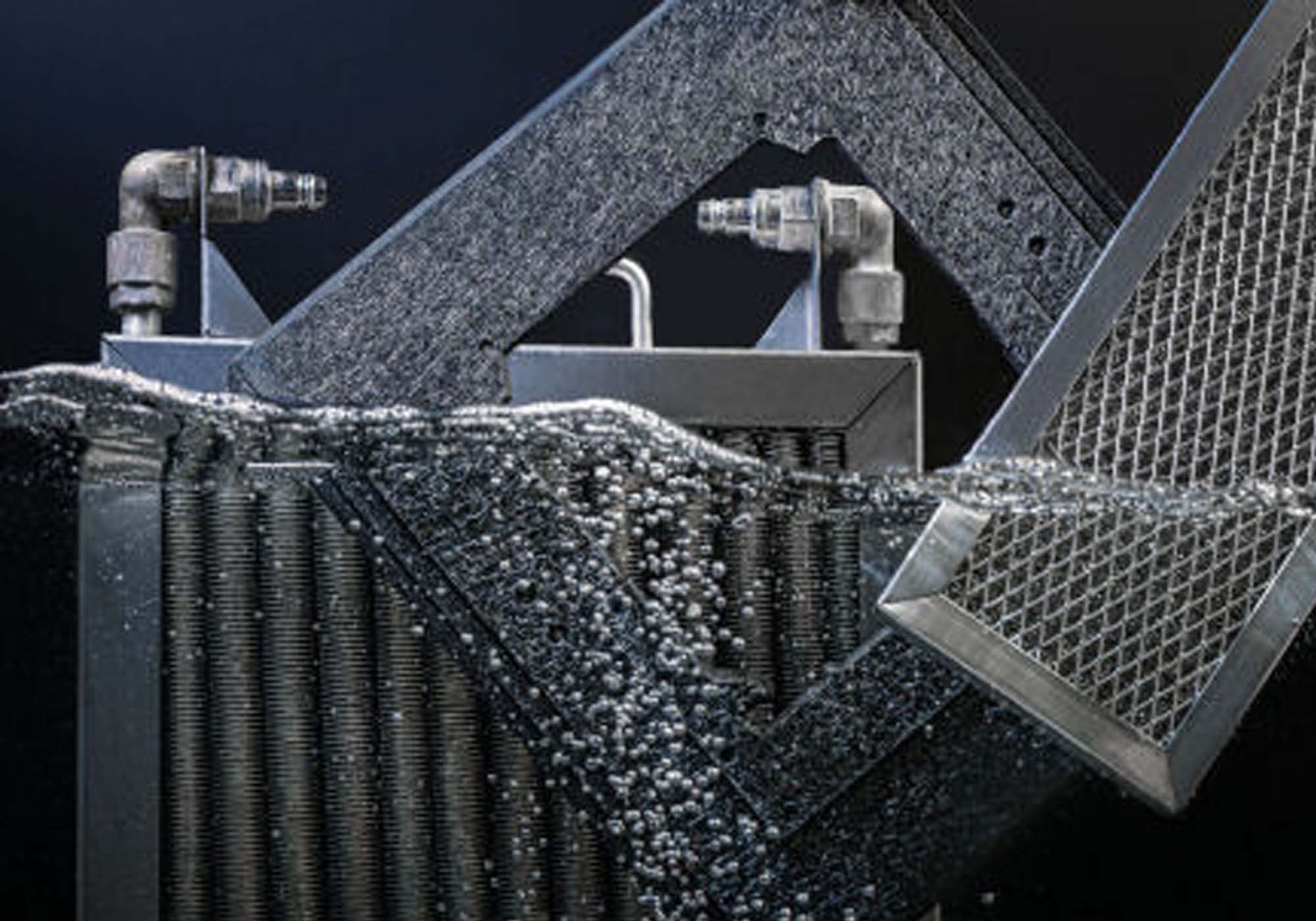

Automotive

The Automotive Industry is highly dependent on specific chemical products and services.

Aerospace

The Aerospace Industry is using a large variety of chemicals, from solutions to services.

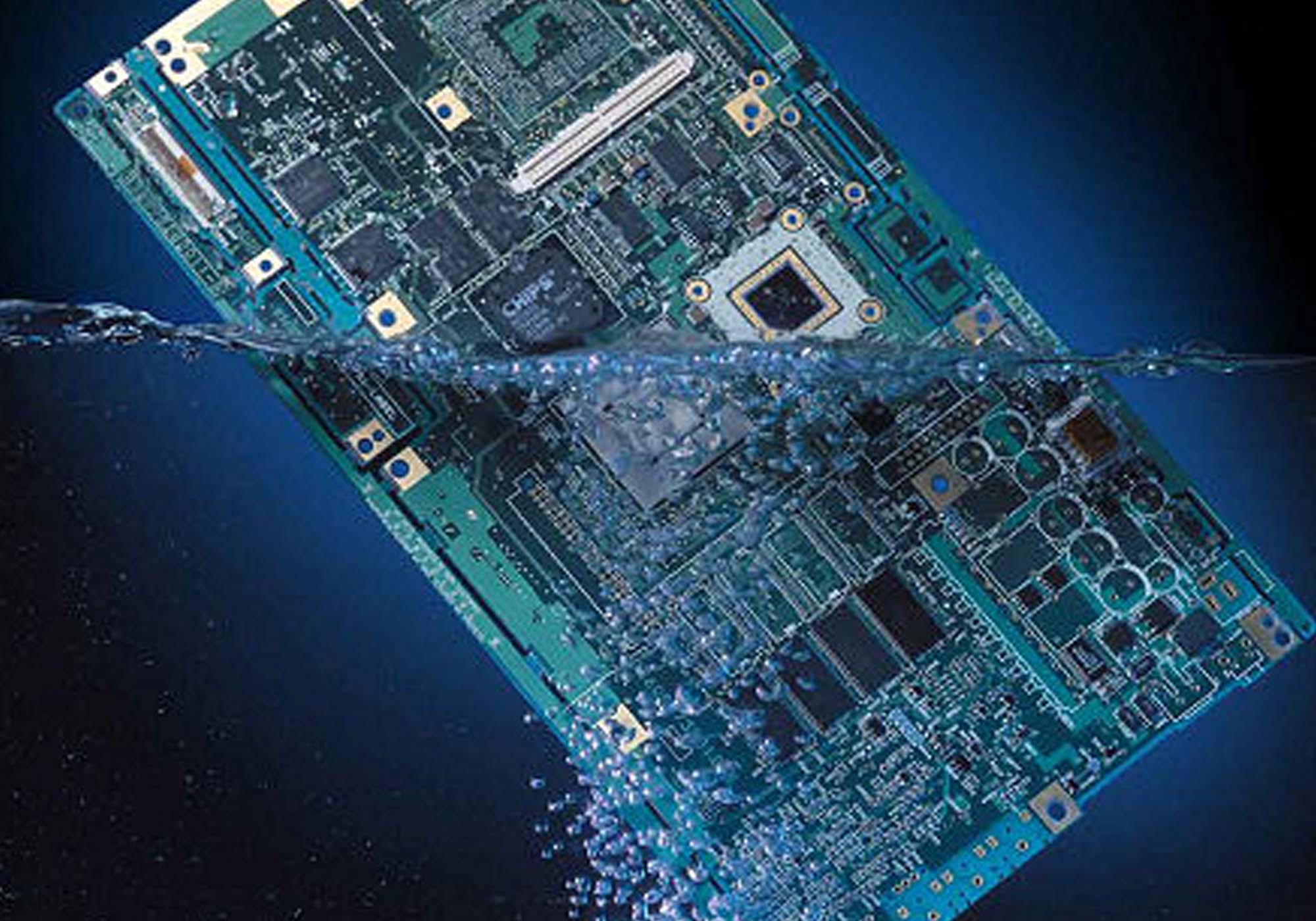

Electronics

Special cleaning solutions are in high demand for the Electronics and EMS Industries.

Medical

The Medical Industry demands high quality services in order to sustain vital care services to patients.

ATRON Cleaning Agents

Water based cleaning mediums for defluxing, removal of conformal coating material from pallets, fixtures, and tools, baked-on flux removal. ATRON products can be used in spray-in-air and spray under immersion processes as well as manual cleaning. The product was developed to improve the cleaning performance and bath life of traditional surfactant-based cleaners, thereby significantly reducing overall cleaning costs. Atron products are ethanolamine-free, enable fast removal of a wide variety of the latest lead-free and eutectic flux residues, have 3 to 10 times longer bath-life than traditional surfactant cleaners, the non-foaming formula does not promote “white scaling”, the gentle formulation leaves solder joints and pads shiny and bright.

VIGON Cleaning Agents

Water-based cleaning medium for flux removal for high pressure cleaning processes, for low and/or medium pressure cleaning processes, manual cleaning, pH neutral, alkaline defluxing agents for PCBs and Power Electronics, stencil cleaning. VIGON® based on the MPC® Technology, is a cleaning agent specifically developed for use in high and medium spray pressure equipment such as inline and batch machines. It removes all types of flux residues from electronic assemblies, ceramic hybrids, power modules, and leadframes. It can be easily rinsed and does not leave any residues on the surface, thereby providing low ionic contamination values on cleaned parts.

HYDRON Cleaning Agents

Water-based cleaning medium for defluxing, pH neutral defluxing agent for semiconductor electronics, water-based, alkaline defluxing for semiconductor electronics. HYDRON® removes flux residues from a wide range of semiconductor electronics, such as leadframes, discrete devices, power modules, power LEDs, flip chips, and CMOS following the die attach process. Easily rinsed with DI-water yielding residue-free surfaces, pH neutral formulation results in excellent material compatibility, specifically with power modules and die surface passivation, retains activated copper surfaces over an extended period of time without risk of reoxidation with no need for waste water neutralization and low odor.

ZESTRON Cleaning Agents

Solvent-based medium for PCB flux removal, SMT stencils and screens, removal of solder pastes, SMT adhesives and thick film pastes. A faster drying time allows for shorter cleaning processes. Its high flash point permits both manual usage and the application in printers and stencil cleaning equipment. It provides a wide process window, high bath load capacity results in long bath life and low cleaning costs, can be used in non heated equipment without external explosion-protection systems, used at ambient cleaning temperatures.It is halogen free, has low odor and a fast drying time. Ideal for removing leaded and lead-free solder pastes from the stencil underside with reproducible cleaning results and residue-free drying, the reliability of printing processes is greatly increased.

Cleanliness Assessment Services

At ZESTRON's Analytical Center, you have the opportunity to evaluate the electronics’ surface cleanliness according to IPC standards, J-STD, MIL or latest industry requirements employing a variety of test techniques. Evaluate PCB cleanliness using various analytical test techniques based on current IPC standards with detailed technical reports documenting assessment and process recommendations. Performed in accordance with the latest IPC standards, ZESTRON offers both “full” board and localized” spot extraction techniques to identify the presence of undesired ionic materials. The testing can be performed on bare PCBs components and fully populated PCBAs.

Cleaning Process Implementation and Optimisation

With thousands of electronic cleaning processes installed worldwide, and an experienced team of application engineers located throughout the world, ZESTRON is uniquely positioned to offer you the technical expertise required to assess your precision cleaning requirements. Eight globally linked Technical Centers offering more than 70 cleaning machines and analytical test equipment from world leading manufacturers are available for your use and evaluation. By conducting substrate cleanliness assessments at our Technical Center and/or detailed process review at your location, our Application Engineers will redefine and document all cleaning process operating parameters to ensure your cleaning requirements are achieved.

Customer Support

Need Help? Chat with us on Whatsapp