Automotive

The Automotive Industry is highly dependent on specific chemical products and services.

Aerospace

The Aerospace Industry is using a large variety of chemicals, from solutions to services.

Electronics

Special cleaning solutions are in high demand for the Electronics and EMS Industries.

Medical

The Medical Industry demands high quality services in order to sustain vital care services to patients.

Solder Paste

Available for a wide variety of process deposition techniques, including

printing, dipping, dispensing, jetting, and pin transfer assembly. Each formula is specifically designed to meet the gamut of manufacturing challenges that plague the electronics manufacturing industry. Whether you are dealing with warpage induced defects, voiding, insufficient solder paste volume, or electrical or mechanical reliability issues, Indium Corporation’s solder pastes – coupled with our world-renowned technical support – allow for the lowest total cost of ownership and fewer end-of-line defects.

Solder Wire

Solid core wire and flux cored wire with a variety of diameters and alloys for

rework, automated soldering, die-attach application, hand soldering and assembly, cryogenic and hermetic sealing. Flux-cored wire is generally used for manual soldering or rework, and is increasingly used in robotic soldering applications. It contains the flux in the center to facilitate the soldering process and eliminate the need for a separate flux. Most of the alloys are available as solid core (no flux in the center). The most popular diameters are between 0.010”/0.254mm and 0.062”/1.52mm; however, SnAg and AuSn alloys are available in diameters less than 0.010”/0.254mm.

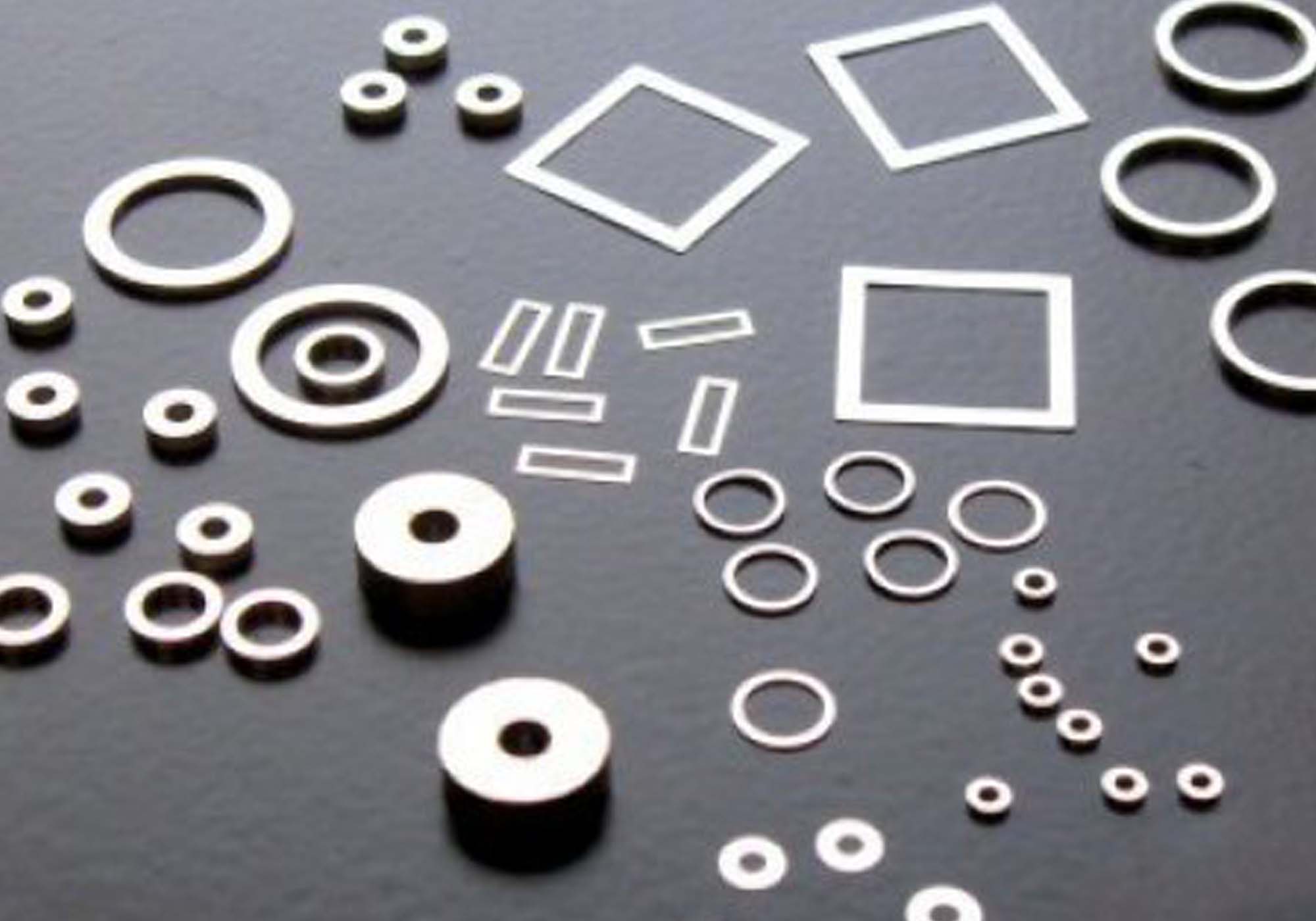

Solder Preforms

Solder Preforms come in standard shapes such as squares, rectangles,

washers and discs. Typical sizes range from .010" (.254mm) up to 2" (50.8mm). Smaller and larger sizes, as well as custom shapes, are also available. Dimensions can be held to tight tolerances to assure volume accuracy. A wide assortment of alloys is available in liquidus temperatures that range from 47°C to 1063°C. Alloys can be indium-contained, gold-contained, lead-free, fusible or standard tin-lead, as well as many others. Indium Corporation has an extensive library of sizes and shapes from which you can choose, or we can create a set-up specifically for your application with you to determine the best alloy for your application.

Fluxes

A complete line of fluxes for soldering stainless steel, copper pretreatments, tabbing and stringing applications, epoxy fluxes used in no-clean SMT component attach applications, flux pens with a spring-loaded applicator tip to deliver a controlled amount of flux to the work surface, POP fluxes for Package-on-Package (PoP) assemblies where the memory package is then either dipped into a specially-designed PoP flux or PoP solder paste, then and placed on top of the logic chip.Also semiconductor fluxes that endure the inevitable physical shocks and thermal stresses associated with electronics devices in applications from mobile devices to next-generation - low-energy servers – to automobile electronics .

Process Optimization

Process optimisation and support

On-site and remote process support is available with highly qualified engineers, know-how based on years of industry-leading experience. Take the guesswork out of process optimisation with Indium Corporation’s analytical tools. Our portfolio of process optimisations calculators and guides are designed to give you actionable data to improve your processes.With Indium Corporation we can use tools like the Solder Alloy Selector Guide, Solder Pot Calculator, Flux-Cored Wire Calculator, Process Optimisation Calculators like RflowCoach, StencilCoach, WaveCoach, AuditCoach, LineCoach, DefectRate and Alloy Density Calculator.

Customer Support

Need Help? Chat with us on Whatsapp